Balzers-Elay: Vacuum technology in the industry

1992/07/01 Aizpurua Sarasola, Joxerra Iturria: Elhuyar aldizkaria

When we talk about new technologies, robots and robots come to mind. Therefore, saying that vacuum technology can be a new technology can result in more than one. Many companies that turn vacuum into technology do not exist in Euskal Herria. In Antzuola we find a company that, in addition to betting on the vacuum, has also opted for the Basque language, Balzers-Elay. The engineer Juan Jesús Alberdi received us there. He was our interlocutor and the content of this article will be heard.

After the decision of the company Elay, located in the municipality of Bergara, dedicated to the manufacture of dies, went to Liechtenstein to contact the company Balzers. Balzers is a company specializing in vacuum technology and coatings, with presence in the US and Europe.

Balzers and Elay quickly reached the agreement and in 1984 the company Balzers-Elay was founded. Although the main shareholder is Elay, Balzers has not only contributed shares but technology. Although Balzers-Elay initially had five or six employees, he now has about twenty-five. Most employees are graduates. The staff consists of a superior engineer, five technical engineers, an economist, a chemist, etc. On the other hand, it should be noted that the staff is very young, with an average age of less than 30 years.

In Balzers-Elay two types of actions predominate. On the one hand, the production of strong coatings and on the other, the sale of pro-ducts from Balzers. While more than half of the staff work in the production of coverage, the rest is dedicated to selling. In the open commercial delegations in Barcelona and Madrid, five people are engaged in the sale of Balzers products.

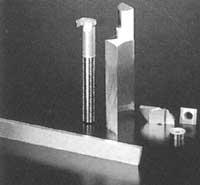

Balinit A and Balinit B (titanium nitride and titanium carbonitride respectively) are the best known in the field of coatings. Among the parts that want to be coated, in general, the cutting tools are (at least in number) the ones that form the largest group, but at the same time the parts for injection, drawing or friction processes are covering more and more. At this time, automotive is the sector that has the most demand.

The coating not only serves to improve hardness but also to improve the characteristics of the parts that must work in friction conditions.

For the correct execution of the covers it is necessary to promote them in vacuum conditions. Joan Jesús Alberdi told us about four vacuum levels. Considering that the ambient pressure is about 1,000 mbar, the normal vacuum level ranges from 1,000 to 1 mbar; the 1 to 10-3 mbar is called the mean vacuum level; the 10-3 to 10-6 mbar is called goihuts and finally, the 10-6 mbar is ultra-fast.

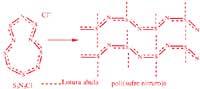

But why do vacuum coatings have better characteristics than coatings in environmental conditions?

Imagine a titanium nitride coating. If we work in the atmosphere of the environment, in addition to titanium and nitrogen, oxygen, water vapor, carbon oxide, noble gases, etc. we will have them. Therefore, the layer of titanium nitride obtained would be full of impurities and would not have the desired characteristics. On the contrary, if titanium and nitrogen are inserted into a chamber where the vacuum has been made, it can be said that in that chamber only two substances will be (considering that achieving a total vacuum is a fiction). The importance of the existence of different vacuum levels depends on the use of coverage.

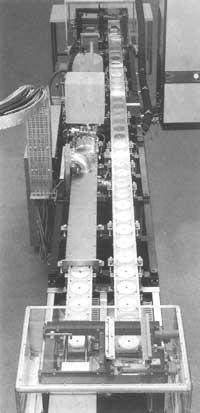

The company Balzers-Elay is specialized in the manufacture of yarns and ultrarraps, and as mentioned above, the tools are those that are mainly coated. The material to be coated must meet a number of requirements. In all cases of coating the material must be clean, that is, without grease, without oxidation, without dirt, etc. In some cases it is necessary that the material can withstand temperatures above 500ºC during the production, since at the time of the coating temperatures can be reached up to 490ºC. Its size theoretically has no limits, but practically in Balzers-Elay, depending on the size of the vacuum chamber, the diameter of the parts is between 200 and 250 mm maximum.

The original material of the parts must be conductive to achieve hardness or friction resistance and microwave is applied before entering the vacuum chamber.

Vacuum chambers must meet strict manufacturing conditions. If the chamber has any type of cleft or cleft, or if the joints lack proper tightness, it will be impossible to descend from pressure. As Joan Jesús Alberdi told us, in Euskal Herria there is technology and wisdom enough to perform these fine tasks, but in the boiler workshops there are “white classrooms”, that is, the technology to achieve a suitable cal-tate is not an ara-zoa, but a culture of pulchritude. Although it does not seem to be very important, the consequences are more serious than serious. For example, in most European projects the boiler factories of the Basque Country cannot participate because the culture of neatness is not known or given importance.

Therefore, when talking about the white room, it is understood that manufacturing products should not be used in any way.

Joan Jesús Alberdi is responsible for the decadent laboratory of Balzers-Elay. The main functions of the laboratory are:

- Forum of staff of private companies or public centers. For this purpose, general or specific courses on debit are taught.

- Show the possibilities offered by the BALZERS equipment to the Indus trio.

- develop research programs in collaboration with public and private companies.

For the development of these activities the laboratory is equipped with different equipment. Among them, vacuum gauges, gas analysis system, halogen leak detectors, mass spectrometer, different topics of coating sis, etc. has them.

Vacuum technology has more applications than mentioned. Some examples are:

- “Research.” In the nuclear and space industry. Solid and physical states of surfaces. Medicine.

- “Electronics.” Semiconductor technology, memories, displays, resistances, receivers, television tubes and solar cells.

- “Optics.” Anti-reflective coatings, mirrors, filters, light and color separators, laser beams, infrared coatings.

- “Metallurgy”. Non-oxidizing steels and special alloys, carbides, heat treatments, welding.

- “Analysis.” Spectrometric mass analysis.

- “Electron microscopy.” Preparation of inorganic samples and preparation of samples of organic biological beings.

In Balzers there are three families of products to work on:

- Components. Units of measurement, control and production of medium vacuum, goihuts and ultra-fast.

- Systems. Coating systems for thin layer technology. Preparation units for electron microscopy. Analysis times. Metallurgical furnaces. Large-scale sis-tems for physical research.

- Thin layers. For optics, ophthalmology, optoelectronics and microelectronics.

Joan Jesús Alberdi told us more things, but he often stressed the need for “new ways of working.” In reality this idea is repeated in all the companies visited.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia