Visit to the Muskiz refinery

2013/10/01 Leturia Yurrita, Iñaki - Elhuyar Zientziaren Komunikazioa Iturria: Elhuyar aldizkaria

"You are entering the industrial estate" says in capital letters the sign located at the entrance of the oil refinery of Muskiz. But it is not any industry. On the one hand, because it is the only refinery existing in Euskal Herria. And, on the other hand, it is not delayed to measure: refines 11 million tons of oil per year, has an area of 220 hectares and distributes the whole of this series in three different municipalities: Muskiz itself, Zierbena and Abanto-Zierbena. The industrial space is so wide that it is unthinkable to move on foot inside. Bicycles, cars and online buses go up and down the streets of the refinery as in a city.

"Eye! You will enter the area of explosive atmospheres", indicated below in the entrance sign. Of course you can't smoke and you have to turn off your mobile phones. Other refineries remove them. Use safety shoes, glasses and fireproof clothing. "We work with hydrocarbons and it's not normal, but it can happen that the gases that flow will accumulate," says Elias Unzueta, head of process of the Petronor refinery. "A spark would be enough to cause an explosion or fire." Therefore, wear jacket that does not accumulate static charges or prohibit the use of electrical appliances. All these measures are established by the ATEX regulations and are strictly complied with throughout the refinery. Everything that can be a source of sparks -- cable, switch, quad-electric -- is isolated. If the mobile phone is used it will use the one that has the "guts" isolated in a box, of half a kilo of weight.

Oil Bank

"In the banks, as in the refinery, oil goes through the tubes, but we do not see it." Unzueta has not lied. Tubes everywhere, kilometers and kilometers, but oil does not appear anywhere. The refinery is associated to the maritime terminal and from there comes the black raw material. There he arrives all over the world: From Mexico, Russia and the Persian Gulf. The refinery was inaugurated in 1972 in order to produce the necessary fuel for the electric generation of the thermal power plant of Santurtzi. The reason for its location was the sea. In the Cantabrian there is not as much depth as in the port of Zierbena so close to the coast. The "superport" is not in vain: It can contain oil tankers of up to 500.000 tons of length and 50 of sleeve. Under water, height of a house of eight floors. These giants empty oil to the refinery through five and a half kilometers of waves.

Today oil, however, practically serves nothing without refining it. Formerly the Sumerians used the asphalt of the streets, in Egypt the leather was cured and the Central American cultures drew it with him. Marco Polo saw a spring leave naturally in the current location of Azerbaidja and so he collected it in his chronicles. It seems that the Chinese were the first to drill and emerge the land. They called Shiyou, the rock oil, and so the father of mineralogy Georg Bauer baptized him the year later: petroleum, oil from the stone, oil or harrollo.

Fossil Chains

The oil arrives from the port to the refinery to 14 green deposits on the return of a bullring. Elías Unzueta has satiated his curiosity: "Each of them includes 100,000 m 3". 100 million litres in cash. But not only oil, but also a little water and, taking advantage that the oil stays on the water, remove the impurity from the bottom.

Its origin is because oil is a fossil fuel: the organic matter accumulated in large quantities in the subsoil millions of years ago and was broken down by pressure and high temperatures, becoming oil and gas. It is a curious element. It is, by definition, a mixture of hydrocarbons, carbon chains and hydrogen, but, beyond definition, the raw material is extraordinarily complex. In fact, a simple molecule like methane with a single carbon atom, as well as heavy molecules with dozens or hundreds of carbon atoms, are part of the same oil.

Among others, the most common hydrocarbon molecules that make up the oil are the altitudes or paraffin, the simplest hydrocarbons, with only simple and saturated hydrogen bonds; the cyclocalcans or napkins, with a saturated ringed structure; the aromatic hydrocarbons, also ringed, but not saturated; and the asphalt, complex and heavy elements.

All these molecules are mixed in black oil. In black, yellowish, green, reddish… because oil is not always black. The color, as well as the viscosity, depends on the molecular structure: the bigger and bigger molecules, the oil will be darker and with many small molecules the oil will return to yellow. Unzueta in his hands has a reddish brown color, almost black. Maya (Mexico) and ural (Russia) are the combinations that are being studied today in the laboratory. However, there is usually no great need for analysis, since once purchased the oil specifications are known. The function of the laboratory is to perform the quality control of the result of the refining and the follow-up of the working processes.

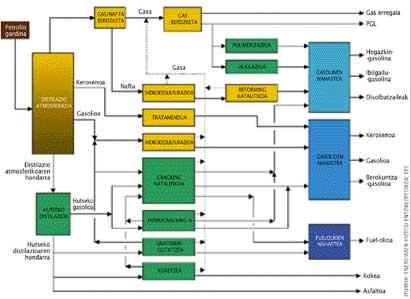

Cook, chop, beat

"The metaphor is good to describe what we do in the refinery," says Unzueta. The preparation of the dish or dishes begins in the distillation tower. It seems like a spacecraft or, following with the metaphor, a pressure cooker of 40 meters of height. Oil enters it at temperatures above 350 °C and a process of evaporation occurs. The lighter products, the smallest molecules mentioned above, go up to the head of the tower and the heavier ones remain in the background. In this height range there are many other products: the different components of oil are condensed at different temperatures depending on their molecular weight. Some trays located inside the tower collect the result of this condensation. This process is also called the division of oil. That is, gases --butane and propane-- (less than 35ºC), naphtas (between 35ºC and 180ºC), kerosene (180ºC-25C), diesel (250ºC-350C) and fueloleum and asphalt (over 350ºC).

This technology is not new, XIX. It has the same base as that used in the nineteenth century. The refining has advanced a lot. Today, to make the most of the oil and produce the products demanded by the market, there are many processes that follow the first distillation. Thus, the Muskiz refinery is said to have a "conversion scheme" because it has 21 different units to transform the oil fractions.

For example, in the vacuum an additional distillation is made to the residual fuel of the tower and asphalt to obtain a greater "juice". Light napkins are used in petrochemicals and with heavy gasoline is manufactured. In the reformed unit the octane of these napkins is improved, that is, the shape of the molecules is modified: by the use of a catalyst containing platinum, the molecules of 6 or 7 carbon atoms of length are converted into rings, since they are better. And so in the rest of units: release and bind chains to obtain petrochemical raw materials, remove sulfur, generate hydrogen... the refinery work is the sum of a thousand small jobs, or less, in quantitative terms. The annual generation of hydrogen is 36,000 tons. Or more than 200,000 tons of sulfur are removed to meet the standards.

The reduction unit of URF or fuel goes on the path of improving performance: the coke tower. In the new facilities, the heavier components of oil are transformed, which is known as the bottom of the tank, to produce lighter products, more demanded in the market from the fuel: liquefied gases (propane, butane), petrol and diesel. This transformation is based on the process of thermal "conversion" of oil. For this purpose, high molecular weight molecules are broken at very high temperature, about 500ºC. Putting the result in figures, 45% of what came out of a Cuba in 1972 was fuel, asphalt and coke and today is 8%, that is, 92% is promise as fuel or for petrochemicals. Or more: The residue of the URF unit, coke, final product similar to coal, is burned by cement factories to generate energy.

Trees in the air

The amount of energy required for the annual distillation of 11 million tons of oil is high, and the proper management of this energy is "of utmost importance", according to Unzueta. "With cogeneration we produce almost 100 Mw using refining gas and natural gas purchased, think about it: Garoña produced 70 Mw". But consumption is also not negligible, almost 65 Mw. They sell the rest of the electric surplus. Petronor has recently launched a project to save energy and reduce emissions from CO 2 due to environmental demands and economic costs. "We want to reduce emissions by 15% or more over the next 4-5 years: 300.000 tons less CO 2 in the air, amount that would absorb a forest of the size of the Bizkaia average", says Unzueta.

Perhaps someone, perhaps a neighbor of Muskiz, would rather see those trees than the chimneys of the factory. But we live in a world of oil thirst and, for the moment, refineries are necessary.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia