The Revolution of the Railways

2006/04/01 Unzueta Garcia, Hibai - Telekomunikazio-ingeniaria Iturria: Elhuyar aldizkaria

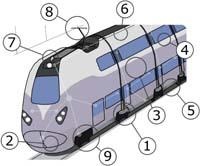

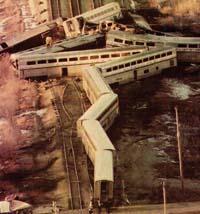

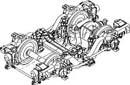

The current transport industry, combining proven concepts in the last decade, has developed new ideas. On the one hand, in the scheme of articulated trains, a wagon separates the bogie with the side. This means that the wagons are not independent and, therefore, will remain united in an accident.

This claim has been possible in all TGV accidents that have occurred to date. The exit of the rail train has been complete and aligned with the lanes in all cases, thus protecting the passengers. This concept has more advantages, such as weight reduction and rolling noise. A classic ten car train will have 20 bogies, while an articulated train will only have 11. Being the heavy element bogies, weight reduction is evident, which allows to increase speed and reduce maintenance costs.

Another concept with multiple advantages is that of distributed traction. In this case, the location of the engines along the entire train is proposed. On the one hand, the adhesion forces between wheels and rails increase, saving energy. On the other hand, since there is no locomotive, more space is obtained for passengers with the same length and weight.

New materials and structures

To date, steel has been used as vehicle construction material, resistant but too heavy. At present, however, with the aim of reducing the cost per passenger and the polluting discharges, the use of two-storey trains tends to increase. For its construction it is recommended to use lighter structures of aluminum compound as in the TGV Duplex or in the prototype Elisa (AGV).

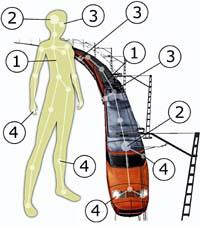

In addition, the Finnish company Fibrocom has developed a lightweight and durable material called channel composite. Special 3D structures are used to maintain the material. From now on, together with Fibrocom, Talgo will also start producing two-storey trains built with this material. It is the first design in the world that keeps the two floors along the entire length of the train, and the steps between cars are also two floors.

Tiltrotator tiltrotator

This technique aims to reduce the effect of the centrifugal force that passengers suffer in curves. This is achieved by balancing the centrifugal force that pushes the train to the outside of the curve, tilting the train to the inside of the curve. This allows to increase the speed around 25%, without the need to modify the existing railways, nor to damage the comfort and safety of the passengers.

There are passive and active tilting systems. The liabilities have been used since the 1980s, for example, in the pendular train of the company Talgo. The boxes of these trains are naturally balanced. The mechanism is that the vehicles have a low center of gravity and the wheels are attached to the top of the vehicle box with a suspension system. In the curves, the centrifugal force pushes the box out and the boxes, being tied from the top, bend inward.

On the other hand, active systems detect that the train is about to enter a curve using GPS or gyroscope used to measure centrifugal force. At that time, through a hydraulic system, the vehicle box is tilted by the bogie. Fiat Ferrocarril (now Alstom) uses this machinery on its Pendolino trains. These trains offer high and medium speed service, mainly in the north of Italy. From 1998 to 2001, Alstom introduced profound changes in classical TGV, leading to the first oscillating TGV in history. The prototype Démonstrateur Pendulaire was subjected to numerous tests for the company to be able to apply tilting technologies to a new generation high-speed train.

Another remarkable novelty in the active systems would be the Intelligent System of Integral Tilting (SIBI) of the company CAF of Beasain. The train consists of a module that determines the position of the train by GPS, relative rolling sensors and the necessary agents to fold the vehicle box with the bogie. The train must first learn the characteristics of the route. In this way, it advances to the route and is balanced at the opportune moment and with the appropriate force. It is a silent and small system, applicable to both electric and diesel trains.

TCN

The Train Communications Network is the meaning of the English acronym TCN. This international standard launched by the International Union of Railways (UIC) and the International Electrotechnical Conference (IEC) defines communication between the internal devices of the train.

According to expert Hubert Kirrmann of ABB Corporate Research, despite the need for standardization of electronic components of the train, the real advantage of the TCN is its capacity for automatic reconfiguration. In fact, trains with a variable composition in the daily service, such as meters, night trains or international trains, require a method of control, diagnosis and exchange of information. This type of communication systems should be configured when the vehicles are connected to each other on the railroad and so do.

According to the TCN, in each vehicle (wagon or locomotive) there can be a network. In addition, a complete rail network connects the networks of each vehicle. This is possible, for example, that from the locomotive it is known that the equipment of air conditioning of the fourth car is deteriorated and that it is informed directly from this fault to the center of maintenance. This last network, which extends to the entire train, is capable of adapting automatically.

And how is it done? Normally the railway network is controlled by the existing link in the locomotive. The links of the wagons located on both sides of the train constantly analyse the incorporation of a new wagon and if they detect something a conflict arises to resolve the control of the new railway formation.

Each formation has its 'strength'. The train formations with more cars are 'stronger', as well as the formations with a driver compared to those without a driver. Therefore, if the formation of detected wagons has fewer wagons or has no driver with the same number of wagons, the weak formation will yield and win the other, which will control the train. Then you will give name to new configuration links to keep them under your control. Thus, the train will automatically adapt to the new size.

ERTMS

In recent years the railway industry and the governments of European countries have made numerous efforts so that trains can cross the borders between countries without stopping. At present, each country has its own Automatic Train Protection System (ATP), that is, its own language to manage the movement of trains. To overcome these incompatibilities, a project promoted by the European Union has been launched which proposes a single signalling model, the European Rail Traffic Management System (ERTMS). But the goal of ERTMS is, in addition to matching European signage, to create the most advanced signaling system in the world with numerous renovations. In fact, at present it is necessary to install expensive equipment, both on trains and along the route. In addition, in the corridors of a lot of traffic, signaling makes the trains circulate more slowly. All this will change with the ERTMS so that rail transport is safer and more competitive.

The full development of the ERTMS capabilities will avoid the need to have the infrastructure adjacent to the railroad (for example traffic lights) that certifies the occupation of the blocks. Through the kilometric beacons located along the route, the train will know its position. This position will be sent to the locking and control centre via GSM-R (version of the GSM mobile telephony system adapted for railways). This center will have information on the state of the network, with the location of each train and the characteristics of the track. The control center will respond to the train by sending orders. These instructions will be a speed profile that will allow the train to know the speed it must maintain depending on its location. The process will be repeated periodically.

To be aware of the power of the system, it must be said that it is ready to work at a speed of up to 500 km/h. In addition, authorities from other countries around the world are very interested in this system, so the ERTMS system may be implemented globally.

WIFI WIFI

The Internet also reaches the train. The high-speed train operator Thalys, the company 21 Net and the European Space Agency (ESA), which works in the Benelux region, are testing to offer passengers a broadband Internet connection.

The prototype features an antenna connecting to a satellite on the roof of a car and a central computer through which it connects to the Internet. For connection the band Ku is used, with the satellite you get 4Mbps down and 2Mbps up. Starting from the central computer of the train a wireless wifi network is established on the train. The connection will be made by laptop and ADSL connection. In addition, on the central computer are available films and other contents for travelers to see on their computers. In the following months, this service will be offered on all Thalys trains and it is possible that soon more trains will be incorporated. In this way, added value will be provided to this means of transport.

Aligned with nature

Scientists see more and more clearly that the residues that are poured as a result of human action harm the dynamic balance of our planet's climate. Once it has been confirmed that climate change is related to the level of CO 2 in the atmosphere, to be able to take measures it is necessary to analyze the sources of pollution. According to a 1998 United Nations report, the transport sector is responsible for 27% of CO 2 emissions.

It seems that trains must offer services of higher speed so that in short distances the car and long is more competitive than the plane. In addition to being possible, less pollution can be produced than in other transports. For example, in 1998 all Swiss trains were electric and 97% of the energy used was hydroelectric renewable energy. The biggest advantage of electric trains is that the energy they use can be generated from renewable sources. But that does not mean that everything is achieved at the vehicle level.

There are numerous measures to reduce the energy consumption of trains. One of the simplest is the lightening of weight, as mentioned above, by using aluminium boxes or lighter electronic components. There are also techniques to improve the union between wheels and viscera. In addition, part of the dissipated energy with regenerative braking can return to the electric grid.

Another important problem is the noise of the trains, a source of noise pollution. According to Japanese researcher Tatsu or Maeda, author of research in the high-speed corridors of Shinkans, the structure of the train and poor exterior design are responsible for noise. A team of the Railway Development Institute (RTRI), under the responsibility of Maeda, highlighted that pantographs and bogies are the most noisy elements of the train. To solve the problem you can build trains with fewer pantographs and fewer bogies like articulated trains. The measures applied in Japan have borne fruit: In 1982 the trains of 210 km/h generated a noise of 79,5 dB, while in 1997 the ones of 300 km/h produced only 76 dB. They seem to be on a good path.

Travelers who have stayed at this hotel

After this journey through the technologies that shape the future train, there is a conclusion. The society needs and will have more rail passengers, both at high speed as in trams or urban meters. Although the use of the train is in the hands of all governments and all people, it seems that this means of transport will recover its space between us. Writer Paul Theroux once said that "the train is not a vehicle. The train is one more part of a country, it is a place." Let the train take us to a better world.