Drawn screens, why not?

2000/07/18 Roa Zubia, Guillermo - Elhuyar Zientzia

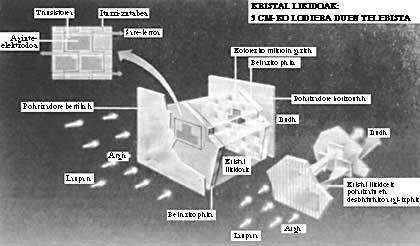

There have been two basic ways to have the color screen for television or computer. The oldest and most widespread thing is to throw colored light rays to the screen using a cathodic tube. This method gives good results, but the device needed a large volume to store the tube. The other method uses liquid crystals. Thin screens can be made, but they offer worse quality and are difficult to make.

New products

Cambridge Display Tecnology (CDT) and Seiko Epson present a new type of screen in London. This is mainly an application oriented to new mobile phones. The basic idea is the use of molecules that are clarified when applying electrical potential. This does not require different light sources, or colored filters, or polarizers. Project technical director Jeremy Burroughes believes they will be easier to make and therefore much cheaper. This technique was developed in his research team in 1989 at the University of Cambridge.

The illuminating molecules are formed by a polymer material (Light emiting polymers, LEP). Thus, the screen is a matrix of polymer drops that provide red, green and blue light. Polymer is called PPV. Its structure has aromatic rings, so they have electron movement and can act as small light-emitting diodes. With Seiko Epson technology, colored pixels are placed on a silicon stand. In fact, they use a very simple technique, since the polymer and the support have contrary electrical charges.

At the presentation, Seiko Epson members showed a small 6.3-centimeter LEP screen with quality color videos from a television. Screens of this size are suitable for use on mobile phones. The CDTs consider that in the development of devices with wireless internet connection they will be able to build economical screens.

It should be noted that until now polymers had a big problem. The lights gradually oxidized, losing the ability to produce color. Therefore, they have been able to build single-color screens. However, current new polymers remain rusted for a long time, according to CDTs, at least during the period of use in consumer products.

Contras

However, the limits are well known. The red light emitting polymer lasts 100,000 hours without oxidation, the green light 30,000 hours and the blue light only 1,000 hours. According to Seiko’s calculations, mobile phones use about 200 hours a year. They say people will buy new phones before the life of the blue polymer runs out. Research to extend the life of PPPs is underway.

The first phone made through PPPs will take approximately two years to market. However, it is expected to be much cheaper than other phones. In addition, they want to develop screens that roll up. To do this, the CDT works with the chemical company DuPont.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia