Binding technology of composites materials

1991/12/01 Markaide, Nerea | Ureta, Esther Iturria: Elhuyar aldizkaria

In recent years the composers have experienced a great boom in different sectors. The metals traditionally used by the aeronautical and automotive industries are being replaced by these new materials in their products. But what are the composites? What are your advantages?

The composites are materials formed by, at least, two different materials: the matrix and the fiber. The general functions of the matrix are to protect the fibers and distribute the stresses uniformly. They can be organic, metallic or ceramic, but the most used are the first and in them resins epoxy or polyester. The fibres, on the other hand, have the function of reinforcing the composite and are organic and inorganic. Among the first there are aramides and among the second, glass and carbon.

Since the matrices and fibers are very varied, the combinations that can be made with both are infinite. Therefore, one of the most important characteristics of these materials is to be able to perform them according to each need.

On the other hand, the use of these materials allows a total reduction of the weight of the finished piece and the obtaining of relatively complex geometry pieces. However, sometimes adhesive or mechanical joints are necessary to obtain specific complex geometries. When choosing one of the two technologies, the advantages and drawbacks of each of them should be analysed, and then, applying to each particular case, an analysis of the selected technology will be performed.

Mechanical joints are widely used in metals, but their application in composites presents some problems: material drilling, oxidation, weight gain and, above all, a distribution of non-uniform stresses. With adhesive joints, on the other hand, the distribution of stresses during bonding is uniform and the weight increase is low. As for composers, although the technique is relatively new, it is today more advisable than the mechanical union.

The adhesive bond consists of the realization of physical and mechanical joints and the definition of the type of adhesive to be used, the surface preparation of the parts, the reinforcement of the adhesive and the design of the joint.

Each adhesive has a different behavior under tension, and before a particular case, the stresses that the bond will bear must be analyzed to select the appropriate adhesive. In some cases, in addition, there may be different degrees of consolidation for the same adhesive, explaining different behaviors.

The adhesives most used in organic matrices are the structural ones, which are reinforced by chemical reaction. The most important are polyurethanes, structural acrylics, cyanoacrylates and epoxides.

Polyurethanes Polyurethanes

... Those of a component are activated by hot or humid way and those of two components once remixed, sometimes by heat. These adhesives are very resistant to shock, abrasion and low temperature, are very flexible and resistant and hardly carry solvents. On the other hand, humidity and high temperatures are not very resistant and are slightly toxic by isocianate.

Structural acrylics

... are formed by two components: the activator extends over the surface of a substrate and the adhesive on the other. Once joined the two is strengthened immediately, obtaining a strong and resistant union without need of heat. However, at high temperatures they have resistance losses, they are very combustible and have a strong smell before their consolidation.

Cyanoacrylates

... these are reinforced with humidity. In addition, substrate surfaces must be basic. If it were acid, there would be no reaction. Very resistant joints are obtained but do not support the effects of most temperatures and solvents.

Epoxis

... its operation is similar to that of polyurethanes. The two components are reinforced once mixed (heat is used as additive) and those of a component by means of heat. The epoxies have very good properties: they resist very well the high temperatures, solvents and humidity, and are able to join most of the materials. They are very rigid, but it must be taken into account that the consolidation reaction is exothermic and can also have storage problems.

For the bonding between adhesives and substrates to be adequate, the adhesive must very well wet the surfaces and for this it is necessary that the surface tension of the adhesive is inferior to that of the substrates. On the other hand, if the surface is not completely smooth, it will wet better.

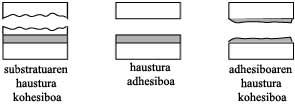

Depending on the type of substrate and its surface state, a bond is broken unevenly and subjected to tension: cohesive break of substrates, adhesive break or cohesive break of the adhesive (Figure 1).

The cohesive rupture of substrates occurs by the poor state of the surfaces or by the low resistance of the substrates. When an adhesive fracture occurs, it is indicated that the bond between the substrate and the adhesive is not adequate, if necessary due to poor surface preparation. In case of cohesive rupture, the greater resistance of the union has been obtained and it can be said that the union has fulfilled its function.

To have the best conditions, it is necessary to prepare substrate surfaces. There are three different ways to get it:

- Degreasing.

- Degreasing and abrasion.

- Degreasing and chemical treatment.

When choosing one of these three alternatives, one must take into account the nature of the substrata. Precisely for organic composites, the most used treatment is degreasing and abrasion, since in most cases chemical treatment is impossible. With degreasing, the impurities that could exist on the surface are eliminated and with abrasion a rough surface is obtained. In this way, the penetration of the adhesive in the substrates is increased. You have to be very careful with abrasion, because if it were too much, it would thin the substrate or the air bubbles would be.

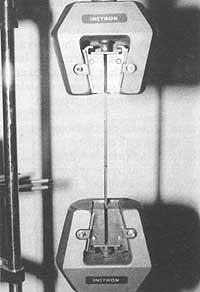

After the surface treatment of the substrates and the application of the appropriate adhesive, it is reinforced. Through this process, the adhesive becomes solid and the conditions of consolidation (temperature, humidity, pressure, ...) depend on each adhesive, usually variables according to the final properties that are wanted to obtain.

As for the industrial process, the reinforcement is made by drying furnaces, presses or autoclaves depending on the size and geometry of the parts, conditions of consolidation and speed of production.

However, before making the adhesive bond, it is necessary to take into account its design and geometry. The adhesive bond in operation can be subjected to different stresses: compression, traction, shear, division and bleaching (Figure 2). Of these, the fragmentation and bleaching voltage supports very badly the joints, so in all designs should be minimized their use. Neither are the tension stresses very convenient. The most resistant are shear stresses and, above all, compression stresses.

The low resistance to the split/bleach voltage is explained by the concentration of the tension at the edges of the junction and by the final break of these points. In other cases, the tension is distributed more uniformly along the entire adhesive and is therefore more sustainable (Figure 2).

Symbolically it can be said that if the joint supports 1000 kg in compression, in shear will be 100 kg and only 1 kg in division/bleach.

After these concepts, it can be affirmed that the treatment of adhesive joints between composites is specific for each case. However, these connections are becoming a conventional technique and have a very promising future.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia