Are materials smart?

2005/02/01 Aranberri, Ibon - Kimikan doktorea | Manchado, Juan Carlos | Garay, Dani | Matellanes, Lina | Dios, J. Ramón Iturria: Elhuyar aldizkaria

Smart or intelligent materials are also known as active or multifunctional materials. These materials are capable of responding to physical and chemical stimuli from the environment. But not in any way. The response must be reversible and controlled. Wood, for example, is inflated if wet, but when dry does not return to the surface. According to this classification, wood would not be an intelligent material, although it responds to an external stimulus.

Intelligent materials are useful for the development of new sensors and actuators, capable of responding to the ‘felt’ quinada and sending information from one side to the other of the structure, and these sensors, in turn, serve to develop new structures, buildings, bridges, etc., analyzing at all times their characteristics. They are already in use.

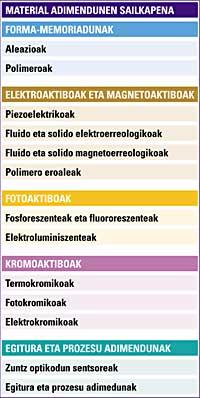

Various types

Intelligent materials can be organic or inorganic, metallic, ceramic or polymeric. Consequently, use can also be unlimited. However, among all intelligent materials, polymers are the most widely used today. In fact, in addition to being light, hard and cheap, they can be synthesized and transformed with relative ease, easily addressing the desired applications.

Some smart materials have the ability to ‘remember’ their shape. They are called with shape memory. Under an electric field or by temperature effect they deform and when cancelling the physical stimulus they return to the previous situation. The best known are the SMA (Shape Memory Alloys or Shape Memory Alloys), but in recent years they are also researching the SMP (Shape Memory Polymers, polymers with shape memory). SMPs have already been marketed in the United States and Japan, but not in Europe.

Others, with similar stimuli, modify their physical properties. For example, electroassets and magnetoassets vary depending on the surrounding electric or magnetic field. Several, piezoelectric, are able to transform the electrical energy of the area into mechanical energy and vice versa.

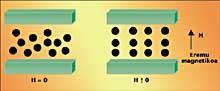

Electrorheological solids and fluids are also sensitive to electric and magnetic fields. They are dispersions formed by particles of about 5-10 micrometers. In the absence of zones, the dispersions are completely fluid, but under the zone the particles are aligned and the liquid acquires the properties of the solids.

Subsequently, once the area has disappeared, the particles ‘loosen’ and the fluid recovers its intrinsic characteristics, in this case the fluidity.

There are on the market, for example, cars with intelligent shock absorbers made of magnetoreological fluids. And thanks to them, it is not necessary to seek points of balance between driving with comfort and safety. In fact, today the safest shock absorbers are also the hardest. Consequently, car manufacturers behave with the minimum legally established safety to increase vehicle comfort.

However, with magnetoreological fluids this need for balance disappears and you can build cars of great safety and comfort. In general, automotive is a very appropriate field for smart materials, as electronics and sensors have been gaining strength.

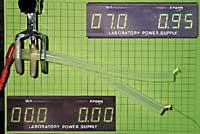

Conductive polymers are also important electroactive materials. Until recently one of the main characteristics of polymers was their insulating character, but not long ago it was found that several polymers could be conductors. Polyethylene, polypirrol and polyaniline are the best known and studied. And in the future many metal cables may be replaced by conductive polymers.

At the moment, they can be found dispersed on mobile phones and flat color screens of new televisions. Made of electroluminescent materials, they have the following advantages: they are light, do not heat and are powerful light emitters.

In any case, it is a powerful field of research in which researchers discovered the conductivity of polymers, a Nobel laureate received in 2000.

There are also drivers who are not conductors but who respond to light rays. These materials are considered photoactive and may undergo variations of various types. Phosphorescent and fluorescent materials stand out.

Both are able to emit rays of light. The phosphorescent materials again emit the light/energy received as soon as they receive the rays and the emitter is switched off (many clockwise, for example, receive daylight and illuminate at night). Fluorescents are white in normal daylight, but if they receive ultraviolet light they simultaneously emit powerful fluorescent light. The electroluminescent materials also become powerful light emitters after receiving an electric current.

Finally there are the so-called chromoactive ones. They are able to change color if they support an electric current –electrochromic–, an ultraviolet radiation –photochromic– or a temperature change –the thermochromic ones–. Logically, once the energy received was exhausted, the material would recover its original color again.

For example, materials that change color with temperature would be of great help in daily life, especially from a safety point of view. The production of pans, coffee machines or glasses with thermochromic materials would allow to easily detect their temperature and considerably reduce both burns and accidents. As for children, both by bottle and bath, they can be very interesting.

Smart labels are also used in packaging to improve product quality. These labels ensure product quality and provide detailed information on production and distribution processes.

On the other hand, the temperature of many products can also be determined according to the color of the label. In England, for example, the Newscastle beer label has a blue star. The label darkens or lightens depending on the temperature, allowing the customer to know if the beer is cold enough before taking the bottle.

Obviously, smart materials have already been used in highly successful applications. New systems and products have been developed, but above all the weight and complexity of the devices already used have been reduced. And it is important to keep in mind that with smart materials you do not want to make totally new products, but it is about making more beautiful, cheap, reliable and, ultimately, more comfortable many of the products on the market.

To this end, the work of university research groups and technology centres will be decisive in the coming years. Basic research from university teams will help us better understand these materials. Technology centers, for their part, should work on the applications of these materials to offer new and better products to society.

In this way, we will move from the age of ‘passive’ materials to that of ‘active’ materials, materials that know how to ‘respond’ and who knows what will come in the future. In the conference on intelligent materials organized by GAIKER, Professor Jan Van Humbeeck announced that, in addition to intelligent or luminous materials, perhaps we will also meet the ‘sages’.

Smart materials in the CAPV At the GAIKER technology centre we work with polymers, plastics and composites. On the one hand, conductive polymers are being mixed with commonly used automotive polypropylene (PP) and polystyrene (PS). The conductive polymers currently on the market have relatively few mechanical characteristics, with the aim of generating plastics with better performance. In addition, magnetoreological and electrorheological materials are being studied. We are developing suspensions with different particles and oils, in order to obtain suspensions such as those existing in the market. In addition to the viscosity of the fluids to be used, it is necessary to control the quantity, weight and forces between the particles. In addition, we are part of a project on magnetorheological solids financed by the European Union. We work with elastomers, a type of polymer. We incorporate microparticles of iron into the elastomers and, later, when establishing a magnetic field, we measure the mechanical resistance that these materials generate. The goal is to get a powerful shock absorber for cars and for the moment the results are encouraging. In addition, together with the Leioa Macromolecular Chemistry Laboratory, we work with piezoelometric polymers and shape memories, synthesizing them and researching their transformation. Often, however, new polymers can be synthesized initially in very small quantities and unfortunately take a long time to market. On the other hand, it is necessary to find companies interested in these new applications and technologies. In fact, although these technologies provide added value to products, small businesses often don't want to get into these kinds of issues. In the Autonomous Community of the Basque Country, the teams that work with intelligent materials have formed the ACTIMAT consortium: MTC, CIDETEC, ROBOTIKER, INASMET, IKERLAN and GAIKER technology centres; Mondragon Unibertsitatea; and the UPV Macromolecular Chemistry Laboratory, the Magnetism and Magnetic Materials Group and the Physical Metallurgy Group (both from Leioa). The group has been led by the GAIKER technology centre since 2000 and is subsidized by the Department of Industry, Trade and Tourism of the Basque Government through the ETORTEK programme. |

Intelligent structuresSmart materials are also used for the design and construction of intelligent structures. In these systems optical fiber is used to transfer information from one side to the other. Optical fibers are highly sensitive materials that can also be used as sensors. They are able to detect temperature changes, different forces, deformations, voltage changes, etc. and transport information. Intelligent structures are complex systems with sensors and actuators. They are able to explain the state of the system itself (temperature, deformation, corrosion...) and to modify some parameters of the material itself (color, shape, hardness...). Consequently, they are able to respond perfectly to the mission for which they have been designed. |

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia