Simulation in manufacturing processes

1988/12/01 Iraola Poirotte, Anouk Iturria: Elhuyar aldizkaria

These market conditions force companies to review and modernize manufacturing processes, automate workshops and restructure manufacturing feet, that is, make large investments. The risk that arises when making these investments is evident and, once the decision is made, it is advisable that it be applied as soon as possible to obtain the return as soon as possible. To do this, and in order to minimize risks, the company will need a large volume of information.

All this has led to the emergence and evolution of the so-called "Computer Simulation Techniques".

The aim of the simulation is to:

Publicize the behavior of a system with the required accuracy and before its manufacture.

Availability

Simulation is used to:

- when it is necessary to modify existing systems or study new systems in the design stage.

- obtain information before taking concrete action, i.e. as an insurance policy.

- to have some measure of possible consequences of decisions.

It is necessary to note that this technique does not have optimization capacity, but redirects the user to the best solution.

Computer simulation is analyzed in specific computer languages such as:

GPSS -ACSL -SLAM -SIMAN-SIMSCRIPT

High-level languages such as FORTRAN are also used.

The field of application of simulation techniques is broad:

- process control

- financial analysis

- market research

- ...

However, its importance in the field of manufacturing should be highlighted.

WHAT IF... " (What happens... well? the analysis section will allow to analyze at every moment the different parameters present in a complex manufacturing environment.

Applications of simulation in a manufacturing process can be:

- Evaluate a system or process not yet implemented, such as the creation of a new plant, the expansion of an existing process or the remodeling of a plant distribution or material flow.

- Provide a permanent and continuous basis for daily decision-making in the following areas:

- changes in manufacturing sequences

- programming strategies

- capacity analysis

- product changes, implementation of new products.

- Staff and equipment needs.

- Location and determination of the size of intermediate stocks and deposits.

- Welcome to the entrance of a new product.

- Identification of production narrows.

- Design of material transport systems.

- Production capacity analysis and alternative production programs.

- Incidence of equipment failures.

Simulation in different manufacturing environments

Based on the above, we can say that: Simulation techniques complement existing techniques in both manufacturing planning and process control.

While in the manufacturing environment MRP-II (Manufacturing Resources Planning) production requirements are well known, the probability of planning being unfeasible (resources may not be adequate) is high. By joining MRP-II with a simulation package, you can make a forecast of the problems that are about to occur. For example:

- production delays by having preferences in resources.

- influence issues that would help an effective strategy to correct delays in production orders.

- check if there is enough capacity to complete certain schedules and whether it is the right time.

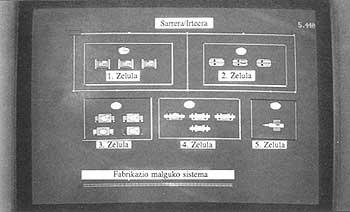

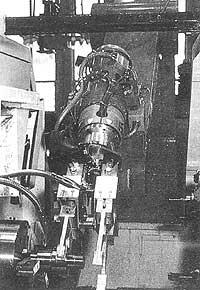

In a manufacturing environment based on group technology, simulation can be of great importance in cell design analysis. Automated cell manufacturing will not work until material movement is minimized and material flow is constant. The simulation would allow redesigning plant distribution and grouping machines by product.

Technical service (Just In Time) will be considered as loss any activity that does not bring value to the product in the manufacturing environment. Therefore, and with the aim of finding a loss reduction, simulation can be used to reconcile production with demand and thus minimize total process time. Simulating plant distribution and alternative configurations, but considering that the manufacturing process must respond to order changes, process time can be minimized. Simulation can be very important when eliminating losses, allowing you to see where an investment can produce.

Standard simulation packages

More and more can be said that simulation is a tool for decision-making.

But any simulation process should follow a few steps. These steps are:

- Create a model that represents the real situation in the simplest way.

- Between the activity of the approximation models by variables that may or may not be activated and the actual activity.

- Get the results of model operation.

- Modification of the actions of the variables to achieve different performances and results.

The development of a simulation model using the aforementioned languages is very complex and requires qualified personnel. Although it is good for everyone, "there is usually no time" for such activities, since profitability cannot be measured immediately. If the so-called “Standard Simulation Packages” appeared on the market, the problem would be solved.

Standard simulation packages are based on a general programming language and the user has no specific programming knowledge. The user can easily work with these programs menus, windows, etc. using. However, its limitation is that although its application in the simulation of the discrete manufacturing process is very simple, the same does not occur in continuous manufacturing processes.

The development that suits the process you want to simulate is simple and fast and will allow you to get quick results.

A very useful aspect of such programs is the graphical representation of processes. This allows you to follow different parts of the simulation, changing colors and graphics. Production shortcomings are immediate as some element of the process is blocked.

To simulate the operation of a process, the following steps must be followed:

- Collection of the most significant workshop data

- Machinery: features, processing time, breakdowns.

- Deposits: raw materials, intermediate stocks, finished products, faculties, management standards.

- Products: types, phases.

- Transport: elements, existing systems.

- Manufacturing: production programs, process plans.

- Modeling the manufacturing process. It presents all the elements defined in paragraph a) and their relationships.

- Machine distribution

- Location of stocks

- Path of transport elements

- Material flow

- Model execution, modifying initial system conditions or operating standards.

- Analysis and exploitation of results. Compare the results generated with the desired results and make the necessary changes in the model to the most suitable operating point.

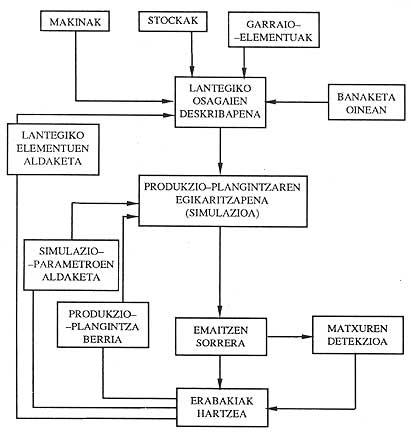

The structure of the methodology is summarized in the following table:

The utility of the model is reflected in the type of responses provided by the program. In general, standard reports are obtained in which, above all, there are percentages and quantities. Reports are generated automatically after a set time. There is the possibility of interrupting the execution of the evolution of the different parameters.

The types of results obtained are as follows:

- Use of resources:

- % in occupation

- % in machine preparation

- % in maintenance stops

- % in breakdown stops

- no. parts manufactured in each machine

- Use of transport elements:

- number of trips made

- % occupation transporters

- Use of deposits and shift waiting:

- tank capacity

- maximum number of pieces that can be stored

- average timeout of product shift

- Temporary distribution:

- maximum, minimum and intermediate process times

- times of each operation

- Raw materials consumed

Final comments

Simulation is an increasingly used technique in Euskal Herria. Companies here, increasingly competitive, are forced to improve their productivity.

DATALDE S.A. is a company dedicated to the organization of companies and their productions. DATALDE uses a special commercial product for its work. For more information, please contact DATALDE directly.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia